Flexible Circuit Prototype

Flex Circuit Prototype is a critical stage in the circuit design process. First of all the design needs to be verified for form, fit, and function. Design Engineers are experts and have advanced software to accelerate this process. The next design function that is typically overlooked before the prototype is Design for Manufacturability. Did you know that a majority of all solder joint rework is directly related to design? Did you know that twisted components are 100% related to design? Did you know that Tumbstoned components are design-related?

So you have automation too!

For customers that have automation in their process, we offer a hand-shake between our data and yours. We offer AOI images of every component in the BOM and electrical test verification to your automation cell. Typically high volume Roll-To-Roll, this is a huge advantage to give your automation the data it needs to pick the perfect parts.

Fudicial Marks

At Automated Assembly® we will take the one-up nesting and add fiducial marks to improve the accuracy of the automation. Fiducial marks help the Stretch & Shrink of the flexible circuit that is inherent in this technology.

Robotic Assembly

We specialize in the robotic assembly and always add vision. As automation experts, we typically have robotic cells in stock, waiting for the next project. With this concept, we grow our end effectors in-house and typically can have a designed solution prototyped within weeks.

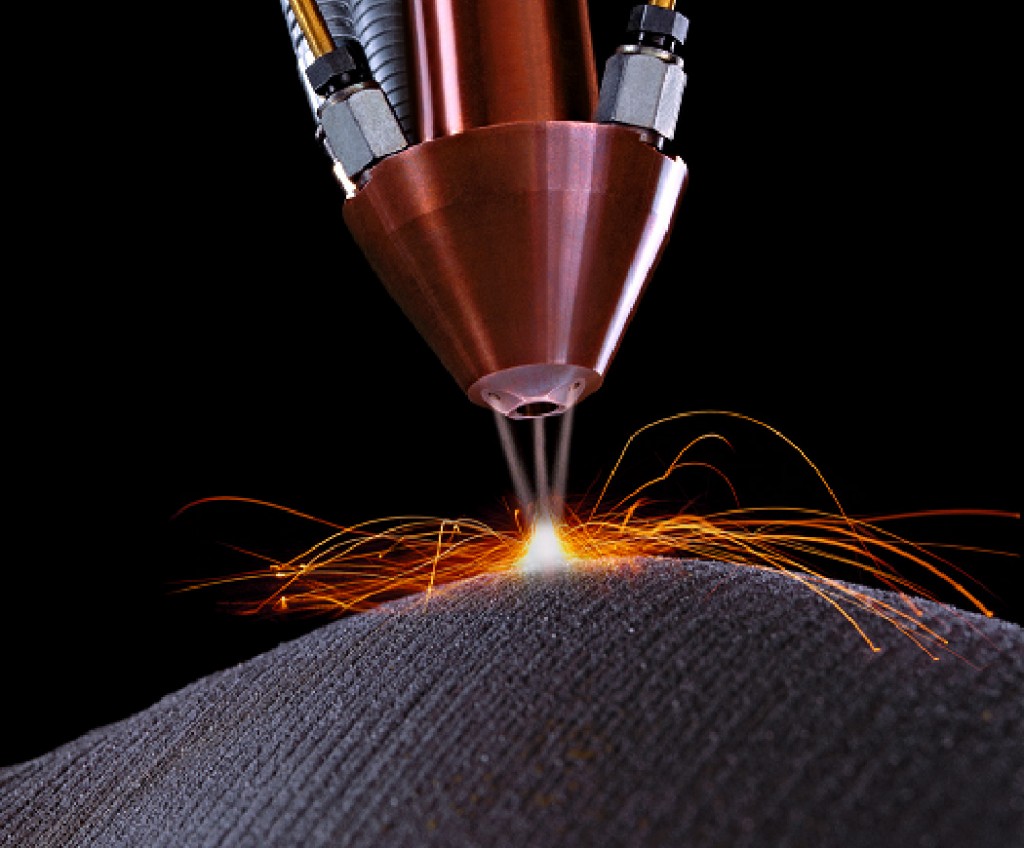

Cutting

We have multiple ways to cut the circuit from the sheet or roll. We offer Rule Die-cutting, CO2 Laser Cutting, UV Laser cutting in sheet or Roll-To-Roll formats.

Traceability

Automated Assembly® continuously invests in new technology. Acquiring the most state-of-the-art equipment is important to designing manufacturing processes that push our own automation limits. Automated Assembly® intends to remain at the front end of new technology and be a leader in electronic assembly on flex circuitry.

Automated Assembly® has many proprietary process for manufacturing on flexible circuitry. Our team of experienced development engineers have worked to refine these processes over the years. Our clients can have confidence in the quality and efficiency of our automation.

We believe that investment in automation is the key to zero defect assembly and continuous cost reduction. We’ve listed some of our most recent manufacturing equipment investments below.

We can offer every level of traceability. For customers that require traceability, we can inkjet 2D matrix Codes, or laser 2D matrix codes into the flex. With this, we will track the build through the process and have traceability to the component level.

3D Cutting

Additive manufacturing is critical to speed and cost. We offer in-house 3D printing for our customers with a variety of plastics. We typically prototype our automation tooling with this prior to production release.

Growing with you

We support all volumes at Automated Assembly Corporation™. We understand the market is not established in most cases when new technology is released. We work with our customers to grow from a sheet process of a few to High volume in the hundreds of millions. As the market grows and shrinks, we breathe with you, adjusting our output to meet your requirements.

Design for Manufacturability

Additive manufacturing is critical to speed and cost. We offer in-house 3D printing for our customers with a variety of plastics. We typically prototype our automation tooling with this prior to production release.

Get In touch With Automated Assembly Corporation™

Start your contract manufacturing journey with Automated Assembly® today. Simply fill out your details and we'll get in touch with you to discuss your manufacturing needs.