Roll-to-Roll SMT-Flex™ Assembly

Automated Assembly Corporation™, a world leader in high volume Roll-to-Roll (R2R) SMT Flexible Circuit Assembly and Polyester RFID technology. Our products are 100 times more reliable in thermally active environments than conductive adhesives. Our Roll-to-Roll (R2R) process begins with rolls that are over 3 football fields in length and only 12″ wide. The process uses 100% optical recognition, eliminating the use of tractor feed systems and expensive rotary punching.

SMT-Flex™: Roll-To-Roll

AAC maintains state of the art manufacturing equipment and trained staff to ensure total production control and precision. Fully automated Roll-to-Roll (R2R) assembly lines are used to process 1,000 ft. master rolls of flexible circuits. The process of populating these large rolls is fast, reliable and very cost effective. All Automated Assembly® robots are designed, fabricated and maintained in house. Over the past two decades Automated Assembly Corporation™ has developed Roll-to-Roll (R2R) assembly and worked diligently to become the first in the world to place IC’s, Flip Chip’s, and standard SMT components in a fully automated Roll-to-Roll (R2R) assembly process.

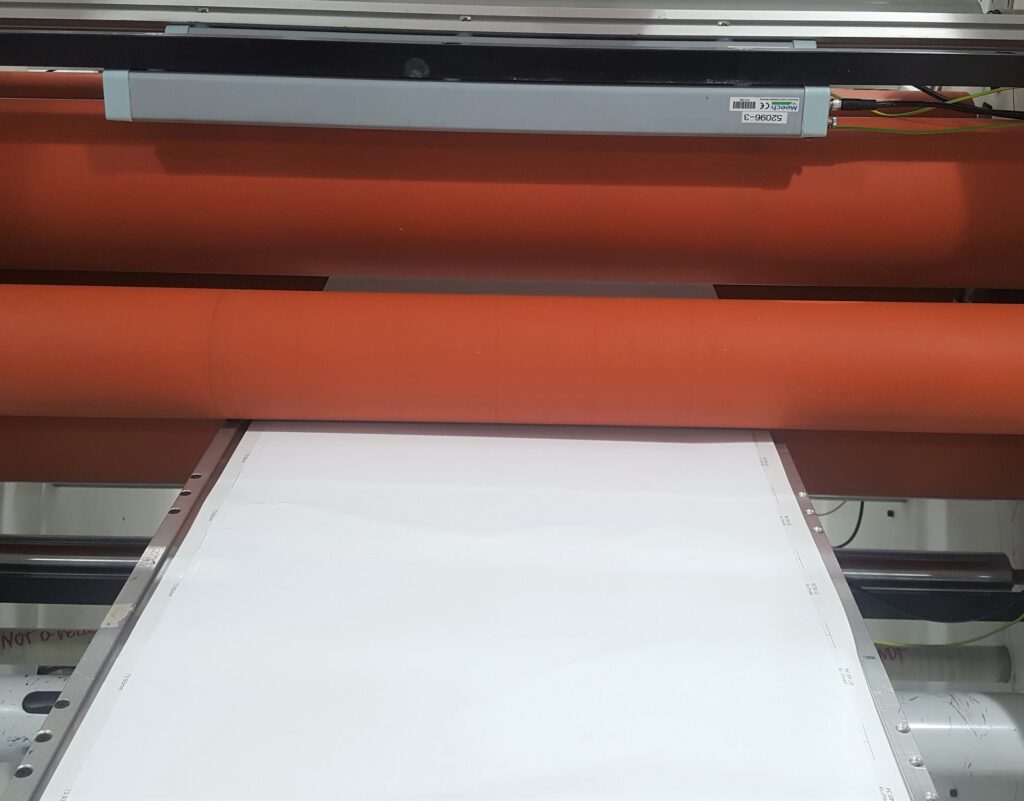

AOI: Roll To Roll

All SMT-FLEX™ Assemblies are 100% optically inspected. Yes, we can pass the inspection data along to your robotic system for seamless manufacturing.

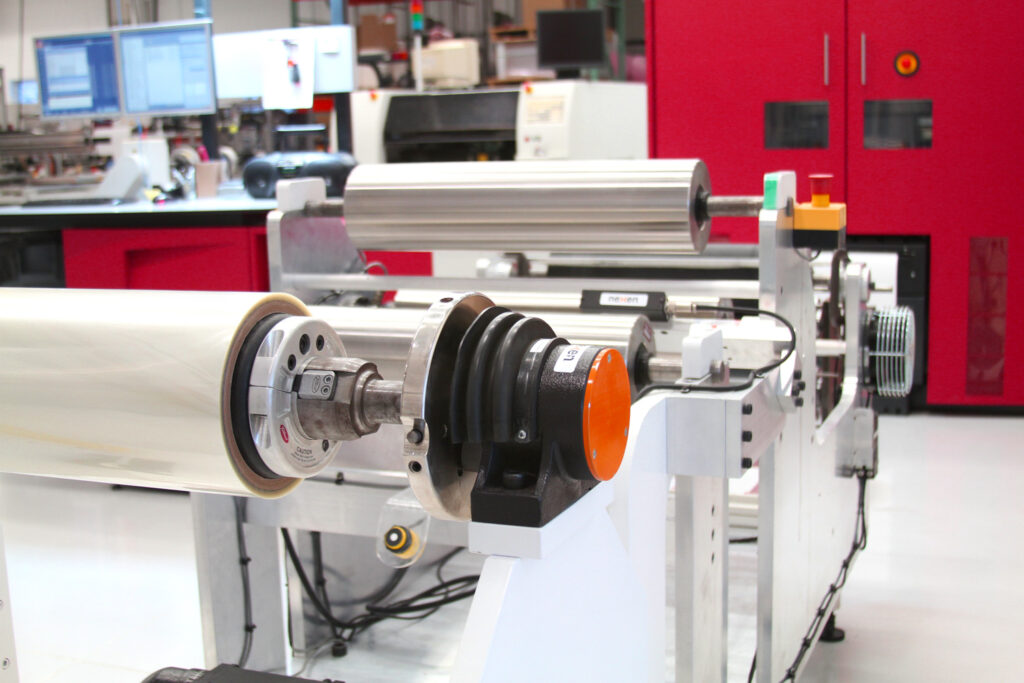

Lamination: Roll-To-Roll

With Optical lamination we provide PSA lamination and top lamination. Each roll is optically monitored for accurate lamination. Heated lamination is available upon request. ESD is monitored and dissipated on each film layer, giving high quality lamination of SMT-Flex™ Assemblies.

Digital Printing: Roll-To-Roll

Digital Printing in Wide Format, or Narrow Format. Our inks are rated for 5 Years. Turnkey solutions for UV Digital Graphics on Roll To Roll Formats.

Die Assembly: Roll To Roll

We are proud to be the first in the world to offer wide format Roll To Roll Die Assembly on Flex.

Get In touch With Automated Assembly Corporation™

Start your contract manufacturing journey with Automated Assembly® today. Simply fill out your details and we'll get in touch with you to discuss your manufacturing needs.