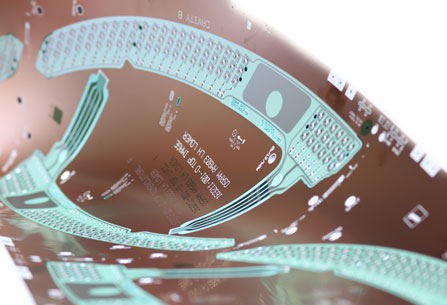

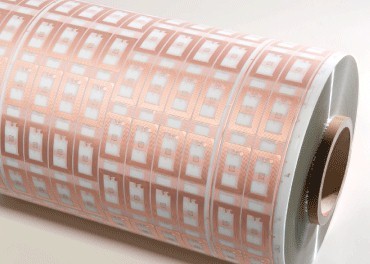

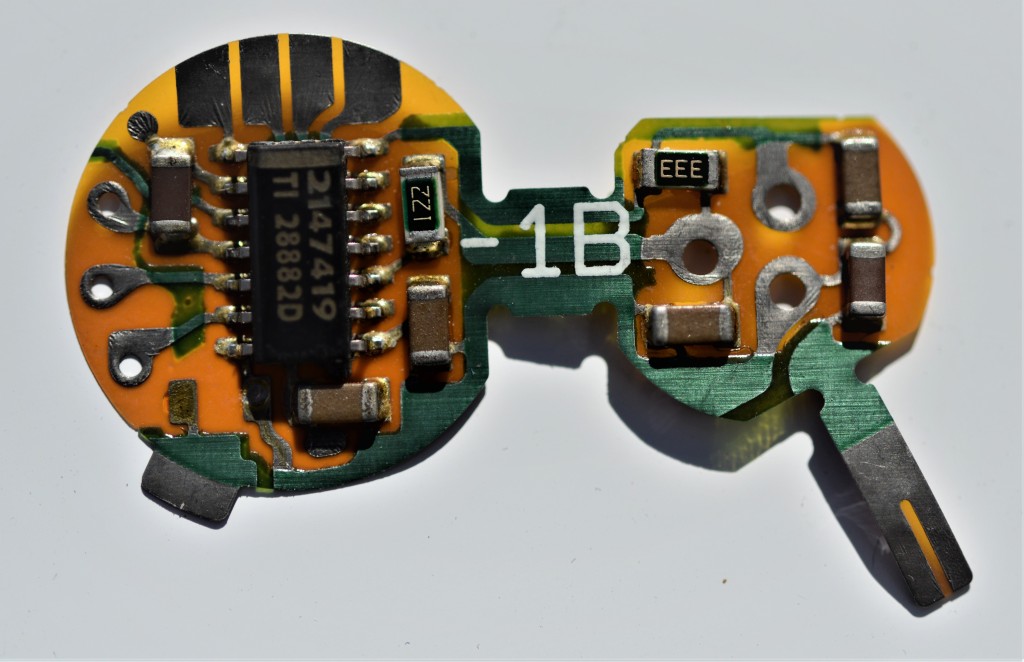

A flexible circuit assembly or flex circuit is a lightweight, thin, and bendable assembly of wires, components, vias, and so on developed on various substrates such as polyester and other thermoplastics. This is widely preferred in small devices with high frequencies. We, at Automated Assembly, have developed SMT-Flex™ to make flex circuit assemblies totally customized to suit specific requirements across industries. This is truly a next generation technology which is advanced as well as cost effective. Our SMT Flex™ technology enables us to make thin, lightweight, durable custom flex assemblies for miniature devices such as wearables, RFIDs, LEDs as well as mission-critical applications such as medical, automotive, defense, avionics, and more. We are capable of high-volume flex manufacturing using Roll-to-Roll processing. Contact us today to discuss your custom flex assembly requirements and we will develop the best possible solution for you.

Types of Substrates

SMT-Flex™ is not restricted only as a polyester flex assembly. We offer it on a variety of substrates that make it lightweight and flexible. Here are some of them.

- Polyester: This material offers a thickness range from two to five mil and an excellent tensile strength. However, its operating temperature range is lower than polyimide and hence is use in applications with moderate temperature ranges.

- Polyimide: This material offers good thermal stability and can withstand wide temperature ranges from a cryogenic environment to extreme heat up to 450 degrees Celsius and beyond. It also has a good dielectric constant and offers electrical insulation. You can make thin sheets of polyimide and these are some reasons why it serves as a great substrate for flex circuits. Polyimide absorbs more moisture than polyester in many applications.

- PEN: This stands for polyethylene naphthalate, and offers an excellent modulus and dimensional stability regardless of the required flexibility. Also, it offers good heat and temperature resistance, largely up to 170 degrees Celsius.

- Paper: This may sound surprising but we have successfully used paper as substrates for our wire-write® circuits. First, it is easily foldable and can be cut into extremely thin layers or as required. However, the folding ability varies with paper thickness. Second, it is cost effective.

- TPU: This stands for thermoplastic polyurethane, and has high tensile strength and elasticity as well as abrasion resistance. It can be developed into ultrathin rolls less than one micrometer.

- Cloth: Just like paper, cloth is foldable and can be formed into thin layers as required. A thin layer of cloth with a conductive metal layer works well as a flex circuit substrate.

Roll To Roll “R2R” SMT-FLEX™

SMT-FLEX™

Benefits of SMT-Flex™ Technology

There are many benefits of our SMT-Flex™ technology. Using this process, we can custom make high volumes of flex circuits using any of these substrates. Here are some of the benefits.

- These flex circuit assemblies can be designed to be highly durable and resistant to extreme temperatures and environments provided the right material is used. Since they are thin, they can be fitted in compact devices, strips such as in LED lighting, and so on.

- Our flex assemblies are made of ecofriendly materials that meet the required norms. They are customer-driven based on the material requirements.

- SMT Flex™ is assembled using the latest SMT technology for high-speed automated placements. In areas where a specialized assembly is required, we manufacture our own XYZ gantry systems and robotic systems for flexible circuit assembly cells. All our automation is optically guided, with all code being written in-house.

- At AAC, we use high-speed robotics for component placement which helps us place sensitive as well as odd-shape components, consider aspect ratio, program rotations, and more while producing high quality product.

- We have 3D printing and full machining capability that helps us save time and reduce cost.

- We offer low-, mid-, and high-volume Roll-To-Roll, polyimide flex assembly, polyester flex assembly, PEN flex assembly, paper flex assembly, and Wire-Write™ Flex Assembly in custom specifications.

- Our processes include graphics, along with optical inspection, lamination, robotic assembly, wire bonding, die from wafer, 3D printing, laser excising, and custom automation cells.

Feel free to contact us via phone or email in case you need further information regarding our SMT-Flex™ Roll-to-Roll assembly process using various substrates or wish to share your requirements with us.

Get In touch With Automated Assembly Corporation™

Start your contract manufacturing journey with Automated Assembly® today. Simply fill out your details and we'll get in touch with you to discuss your manufacturing needs.