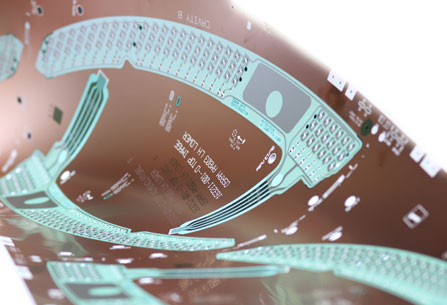

LED Strip

Automated Assembly® has manufactured the tail light LED Assembly for the Aston Martin since 2007.

Automated’s LED Strip Assembly engineers have developed a process that enables soldering LED’s to lower temperature substrates such as Polyester and PEN. Our unique reflow process protects heat sensitive components from thermal degradation.

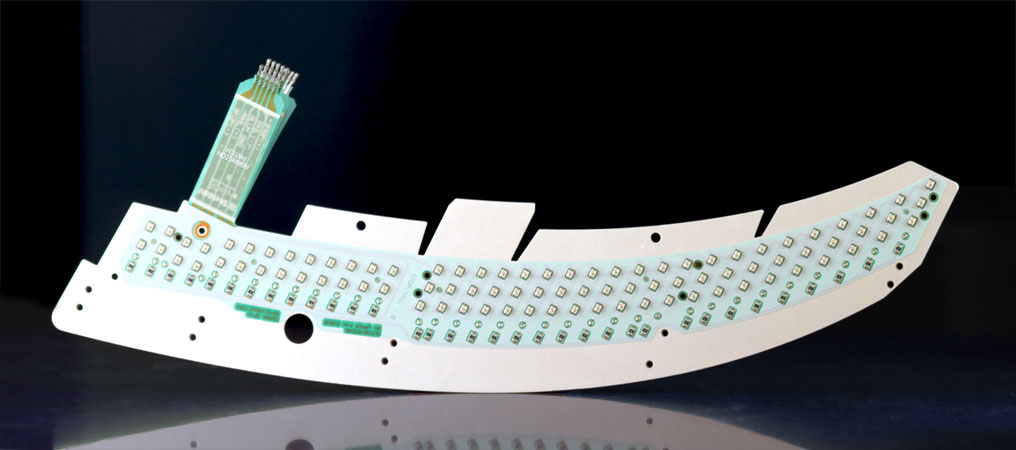

LED Flexible Assembly

AAC has also developed a reel-to-reel robotic manufacturing process that ensures placement accuracy of LEDs with a high throughput rate. Reel to reel assembly delivers a highly efficient product by creating 1000 foot rolls of LED strip assemblies for our client’s manufacturing lines. This streamlined process helps keep costs low.

LED Manufacturing

Flexible Circuit Manufactured in Reel-to-Reel SMT Flex® technology is one of the most rugged inter-connect technologies available today. Our products have been tested in extreme conditions without failure. This combination of durability and cost effectiveness make Reel to Reel illumination ideal for ultra high volume applications. This solution is perfect for markets like automotive, which manufacture for operation in tough environments.

LED Strip Manufacturing

High Volume Roll-To-Roll LED Strip Manufacturing by Automated Assembly Corporation™. We meet the high volume and high-quality demands of the Automotive and Aerospace markets. Designed for continuous manufacturing with the elimination of splices to offer our customers the Best-in-Class quality.

Manufacturing LED Strips

Automated Assembly Corporation™ is a custom manufacturer of high volume and high-quality LED Strips. In fact, we have eliminated all splices in our SMT-FLEX™ LED strips to offer our customers premium quality lighting. As a matter of fact, we start with five-hundred-foot master rolls of materials and eliminate all splices in the end product to our customers. The #1 quality concern of splices has been eliminated.

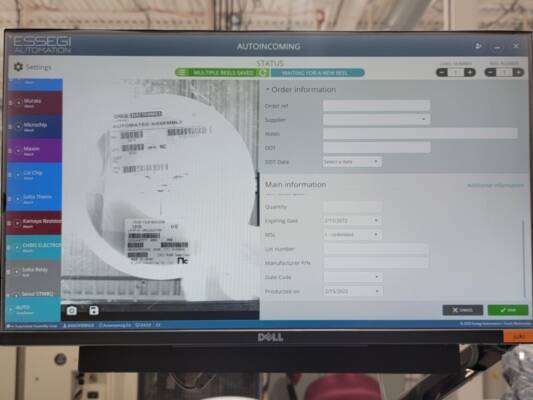

Traceability For LED Light Strips

As the quality requirements go up, so does the requirement for traceability. In our automated process, we offer full traceability to customers who demand the best. Starting at receiving inspection our AI software verifies every Label, Bin, Manufacture, date of manufacture, and Color temp to make sure the quality standards are being met. For assurance we photograph every reel, and link with the strips being manufactured. If you ever have a quality problem, we have you covered with our 100% traceability. For your Quality Engineer we offer Apps to 100% track everything that is important to your custom LED strip.

AI Inspection of LED Reels

Quality starts are receiving inspection. Every label is 100% verified with Artificial Intelligence software to confirm the LED’s are correct from the manufacturer. We verify every part number, Date of Manufacture, Lot Number and keep all records for our customers.

World Class LED Manufacturers

Our customers have great design teams and pick the best LED from around the world. Our job is to have the LED Manufacturing Technology for mass production with all approved vendors. From low volume manufacturing to high volume LED manufacturing, we support all high-end LED Manufacturers. Our Reel-To-Reel technology keeps trending with the times, always placing smaller and brighter LEDs. From wafer level to packaged die, let our team assist your application.

Single Lane Testing

Spooling and single-lane LED testing is an everyday event at Automated Assembly Corporation™. Our custom manufactured LED strips are 100% tested. Our single-lane testing can fill the requirement from simple on/off testing to lumen output and color. We back up our data with customer-supplied apps, so your team can see real-time the quality on the line.

AOI FOR LED's

High volume LED Manufacturing requires Automated Optical Inspection. At Automated Assembly®, 100% of every LED is optically inspected. Manufacturing to the latest IPC standards, our customers specify Class 1, Class 2, or Class 3 assemblies.

Made in the USA!

Sorry, we do not sell our LED strips to the open market. Our business only supports Business to Business. Our typical customers are high volume consumers of LED Strips in the Automotive, Aerospace, Commercial Lighting space. Our minimum roll length is 500 feet by twelve inches. If you are looking for fully automated Roll-To-Roll LED Strip Manufacturing in volumes over 6,000 feet per order, we are here to assist in your next project.

Get In touch With Automated Assembly Corporation™

Start your contract manufacturing journey with Automated Assembly® today. Simply fill out your details and we'll get in touch with you to discuss your manufacturing needs.