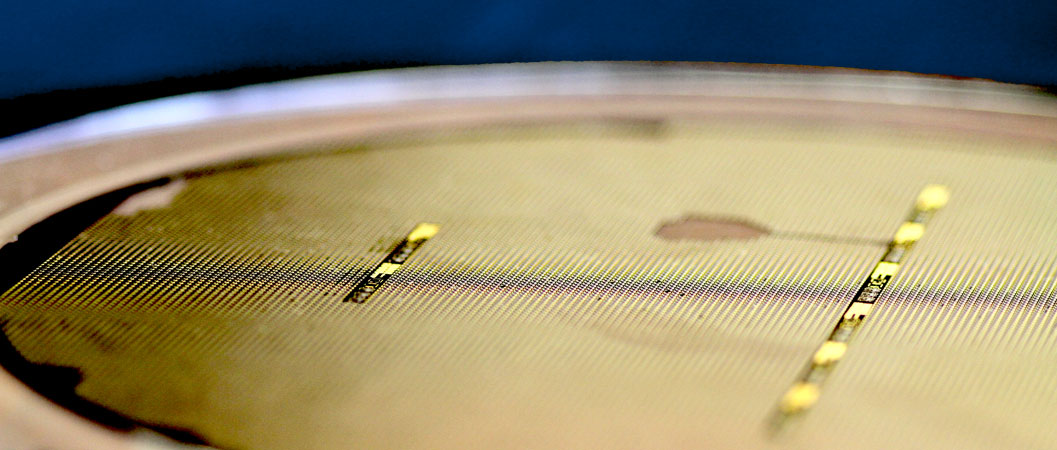

Flip Chip on Flex

High volume flip chip Assembly on flex circuitry is routine at Automated Assembly®. The original roll-to-roll process developed at AAC was created specifically for flip chip assembly onto one thousand foot rolls of circuitry. The flip chip die is bonded using solder inter-connects to a variety of substrates including Polyimide, PEN and even Polyester materials.

Flip Chip Bonding

The use of solder for bonding flip chips is recommended because the inter-connect has good mechanical strength and superior electrical performance. Conductive adhesive may also be used as an inter-connect when assembling flip chips. The electrical and mechanical properties of conductive adhesive are not as robust as solder, however conductive adhesive bonded flip chips may be suitable for ambient environment applications.

Flip Chip RFID

Our flip chip assembly provides unlimited possibilities for creating quality products that match your design and cost parameters. Some applications may include: Radio Frequency Identification (RFID), Smart Cards, Hearing Aids, Toll-way Tracking, Cell Phones, Credit Cards, Video Gambling, Automotive, Satellite TV, LAN, or WIFI Technology. In addition to its application, flip chip on flex technology can be used in a wide variety of markets requiring RFID or micro-electronics including:

- RFID

- Medical Applications

- Telecommunications

- Consumer Products

- Sensors