Laser Cut

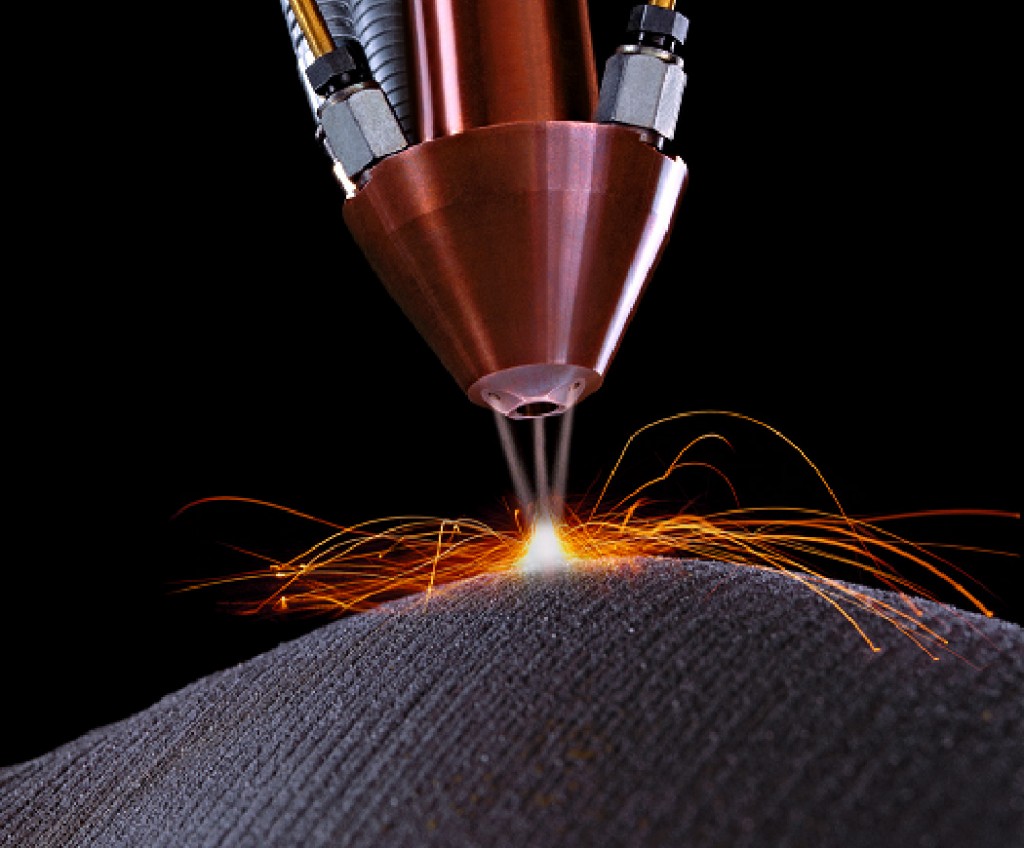

Automated Assembly® Corporation has laser cut and excising capability. This capability saves time and money by eliminating the process of tooling. AAC provides fast turn prototypes with high quality part definition. Our laser system has vision registration and high accuracy repetition. Laser cut products are available in discrete part or in roll to roll form.

This laser system enables intricate outline or cut line definitions that were not possible with tooling. Products can be “kiss cut” on an interleaf liner so that parts can be delivered on a roll and then peeled off for assembly.

Laser Cut Sizes

AAC has intelligent buffer with automatic data compression which stores your files with all the settings; files are addressable and repeatable in any order and then may be deleted after completion to free memory. Buffer can be switched to single file mode. Our LCD display shows current file name, laser power, laser speed, run time, files loaded, and diagnostic menus. Our current largest maximum part size laser dimensions are 37 inches wide by 23 inches deep and 9 inches thick. Our machines have the ability to Z-axis, auto focus; X-Y beam positioning with racer motion technology, and enhanced vector cutting with system status indicator for optimum performance.